Marina Systems Product Overview

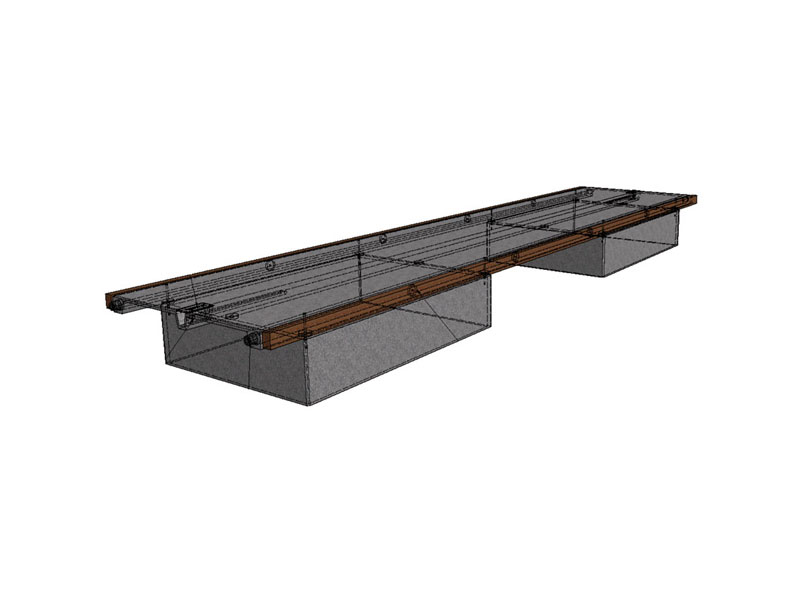

Our Marina Systems are a step above the typical wooden, aluminum or steel dock systems you’ve seen. We offer a complete line of all-concrete single-cast designs, with EPS styrofoam cores and protected steel reinforcements. The heavy mass of the structures offer stability and longevity. They are low maintenance, and accommodate high vessel and environmental forces; including high winds, waves and harsh winters.

Our marina structures are aesthetically pleasing to view and feel under foot. They are customized with wood and composite treatments and a thick deck surface to accommodate internal utilities, lighting, high-loading cleats and bollards, and small cranes. If you can cast it into concrete, we can design for it!

Technical Considerations

- Freeboard heights from 10” to 38”

- Widths from 8’ to 32’

- Customizable lengths up to 100’ single-cast units

- A thick concrete deck surface accommodates internal utilities, lighting, high loading cleats and bollards, small cranes

- Anchoring Systems include chain and bottom anchors, pile mooring, and helical with elastic rode mooring systems

- Proven cable connector system for endless dock lengths

SF 1000 Project

Boston Yacht Club

- Marblehead, Massachusetts

- 1985/2018

- SF 1024 & 1050

"SF Marina docks have performed well in this rough location for decades. The wide, heavy, stable floats add to the BYC experience.“

The Boston Yacht Club dock is made up of multiple types of 1000 docks. The older sections are various sizes including 1024-10m, 1050-10m and a single section of 1050-20, which is the newest addition. These units are combined with multiple connector types to from a 15' x 200’ main dock and approach dock.

The Boston Yacht Club has a long history with SF Marina Systems, which dates to the early 80’s. The club is located in the popular sailing harbor of Marblehead, Massachusetts and has thousands of moorings which are served by club launches.

Located on the western shore, the Boston Yacht Club is exposed to “Nor'easters” conditions throughout the year. The SF Marina dock system was designed to serve the club's fuel, member pickup, launch, and dinghy docks. The system is moored on heavy chain, and left in place year-round serving many regattas and events.

SF 1200 Project

Princess Marina

- Hamilton, Bermuda

- 2014

- 70 slip marina, vessels from 25’ to 100'

"The marina rode out Gonzalos, a strong category-two hurricane, with no damage."

The Princess Marina system was assembled from 1230 and 1240 docks, and 4' wide concrete fingers which were single-cast up to 60’ in length. The marina was designed with freeboard of 25” to accommodate larger vessels.

The 10' wide walkways provided ample room for utility pedestals and golf cart access. The fuel dock width of 14' will accommodate a small building for multiple fuel dispensers.

Shortly after the marina was installed, a strong category-two hurricane, Gonzales, tore through Hamilton with no resulting damage to the docks.

Botelawood Architects of Bermuda coordinated the design, Correa Construction of Bermuda performed the installation and SF Marina Systems USA designed, supplied and installed the floating dock portion.

The strong, single-cast design of the 1200 docks provide the increase strength and freeboard desired by the owner; exceeding the 120 mph storm design criteria.

SF 1500 Project

Gurneys Marina

- Newport, RI

- 2017

- Type 1540 moored on pile 14’x 230’

The Gurneys Marina was assembled from multiple SF Marina system’s components. Type 1540, for the Mega Yacht dock, Type 400 Floating Breakwater, Type 1030 concrete docks, and high freeboard concrete fingers.

The unique design called for freeboards ranging from 7 inches to accommodate the sloped sport/paddle dock, up to 30” for the mega yacht dock. Solid Cast Concrete 50’ fingers were manufactured with 75 degree angles to provide a better approach for docking yachts.

Harbor Engineering prepared the layout design, and Reagan Construction accomplished the installation. A full range of utilities from 100 amp 3 phase power, water, pump out and fire standpipes were accommodated 100% internally via the custom designed ducts system.

The Marina location is exposed to the Northern fetch of Narragansett Bay, which can produce significant waves in the off season months.

X-Line Project

Norden Bay Marina

- Norden Bay, Germany

- 2014

- 2.4m x 12m sections

The X-line dock uses a new patented technology, incorporating basalt rebar reinforcements in the single-cast concrete structures. The advantage of this design is the absence of corrosive metals in the structure. The lifespan of the dock is double compared to a traditional steel-reinforced docks.

The marina owner wished to replace their aging aluminum dock with a longer lasting concrete solution. The multi-phase project will eventually replace all the older docks with the new X-Line system.

ProDock Project

Basalt Reinforced ProDock System

- Llaxhall, Sweden

- 2014

- 2.4m x 10m sections with steel fingers

The ProDock is a lighter duty, all-concrete dock system that utilizes a single-cast concrete floatation module, and a single-cast deck section reinforced with basalt rebar. A simple stainless steel center joint connects the units. The dock system is designed for calm water locations and may be moored on piles, chain, or elastic mooring systems. This dock is a cost effective solution that is easily shipped and assembled.