Floating Breakwaters Product Overview

A complete line of heavy duty all concrete single-cast floating breakwater with EPS styrofoam core and protected steel reinforcement. The heavy mass and thick walled concrete structures offers stability and longevity while attenuating waves to provide a calm protected harbor area. They are low maintenance and accommodate large vessels and environmental forces, including impacts, high winds, waves and harsh winter ice.

The floating breakwater systems are based on SF Marina’s Industrial docking systems, enhanced with greater depth and mass to stop wave energy. Floating breakwaters double as marina and industrial docking systems.

Technical Considerations

- Freeboard heights from 20” to 30”

- Widths from 10ft to 42ft

- Draft depth from 4ft to 12ft

- A thick reinforced concrete deck surface accommodates internal utilities, lighting, small cranes, mooring bollards and large capacity equipment

- Anchoring systems include chain and bottom anchors, pile mooring, and helical with elastic rode mooring systems

SFBW 300 Project

Newport Yacht Club

- Newport, Rhode Island

- 2013

- 10' wide x 6' tall x 230’ long

“Working with SF Marina Systems, the Newport Yacht Club and the Float & Dock Committee, we were able to accomplish a floating breakwater solution that exceeded our expectations. The membership is happy.“

The Newport Yacht club needed to do extensive maintenance to its fixed 10’ wide wooden wave fence, which had come to the end of it practical service life. The club desired a floating solution to escape the issues of the tidal fluctuation, and to improve the view from the marina to the harbor. In addition, greater attenuation of the wave conditions was needed. Working within the existing permit lines, and with the enthusiastic do it yourself club, a 3m wide floating breakwater was designed and attached to member-built wooden fingers on the back side. The result was a cost effect systems that accomplished the goals of the club.

SFBW 300 Project

Conanicut Marine

- Jamestown, Rhode Island

- 2016

- 16' wide, 168' floating breakwater

Conanicut Marine upgraded an old timber dock to a floating breakwater. The dock also serves yachts up to 120'.

SFBW 300 Project

Hyannis Yacht Club

- Hyannis, Massachussets

- 2018

- 10' wide x 135' long floating breakwater

Hyannis Yacht Club replaced a tired modular concrete dock with a floating breakwater to protect the interior timber docks.

SFBW 400 Project

Save The Bay - Narragansett Bay

- Plymouth, Massachussets

- 2013

- Type 400 with 48’ SF concrete fingers moored on piles

"Working with SF Marina System was a seamless process from design, to delivery and installation. Mason is one of the best partners Save The Bay has worked with."

Save The Bay is a non-profit organization that is an advocate and educator for the Narragansett Bay. Their waterfront location and existing docks were exposed to a considerable fetch and waves, prohibiting the boarding of outreach vessels on rough days, and causing damage to the wooden docks. Working with SF Marina Systems, a Type 400 floating breakwater was deployed (by Reagan Construction), providing shelter for the docks. With the calm water behind the attenuator, additional boats can now be left on the wooden docks, including the Johnson and Wales college sailboats. The improvement has allowed great educational and outreach projects to proceed. Save The Bay plans to enlarge the system by connecting with a fixed pier, to provide more public access to the water.

SFBW 400 Project

Brewer Marina

- Plymouth, Massachusetts

- 2013

- Type 400 with 48' SF concrete fingers moored on piles

“After years of costly annual maintenance on my interior marina systems, this is first year I have had no maintenance.”

Brewers Plymouth Marina had an aging marina system that was repeatedly damaged in storm events, creating a lot of expensive maintenance. Hurricane Sandy eventually destroyed much of the existing dock. SF Marina systems has provided a new floating breakwater for a Spring 2015 installation. Fitted with internal and external piles, the new system has seen multiple strong storms with no damage or maintenance issues.

SFBW 400 Project

Massachusetts Maritime Academy

- Buzzards Bay, Massachusetts

- 2018

- 14' wide x 180' long floating breakwater, 36" steel pile

Massachusetts Maritime Academy improved it's waterfront with a new floating breakwater. The exposed location on Buzzards Bay can experience waves over 6' 9". 36' steel piles hold the system in place. THe floating attenuator also serves the multiple training vessels as dockage with utilities and industrial fendering.

SFBW 500 Project

Carolina Yacht Club

- Charleston, South Carolina

- 2013

- 700’ of 16’ wide floating breakwater, moored on heavy chain

The Carolina Yacht Club, one of the oldest yacht clubs in the country, is located in Charleston, SC. The club members wished to expand the docking area of the marina, to increase the amount of slips. The location had a 5-mile fetch and opportunity for significant waves, so a wider floating breakwater was required. The combination of the 5m wide floating breakwater and the heavy chain anchor system accomplished their goals. One notable trait of the pile-free system is the clear views over the bay, and the ability to roll large sails directly on the docks.

SFBW 600 Project

Provincetown Marina

- Type 1240, 1260, 500, and 600 floating breakwaters

“The Provincetown Marina was designed and built to be protected by floating breakwaters on a year round basis in one of the toughest winter environments in the Northeastern USA, the breakwaters are performing as planned”

Chuck and Ann Lagasse overhauled the old Fisherman’s pier in Provincetown Ma. The Two phase project in total has over 2000’ for concrete floating docks, with over 650’ of this total as 16-20’ wide floating breakwaters.

The Type 600 Breakwater is moored on 36” piles, and has a draft of 6 ft. It protects Multiple 80’ wooden slips which can accommodate yachts over 100ft long. The along side berths can accommodate Super yachts and have a full compliment of utilities and power to service these larger vessels.

Provincetown harbor is long know for its ocean generated storms, which can produce strong aggressive winds that will whip up sizeable waves in the harbor. The width and size of the concrete floats have proven well in these conditions.

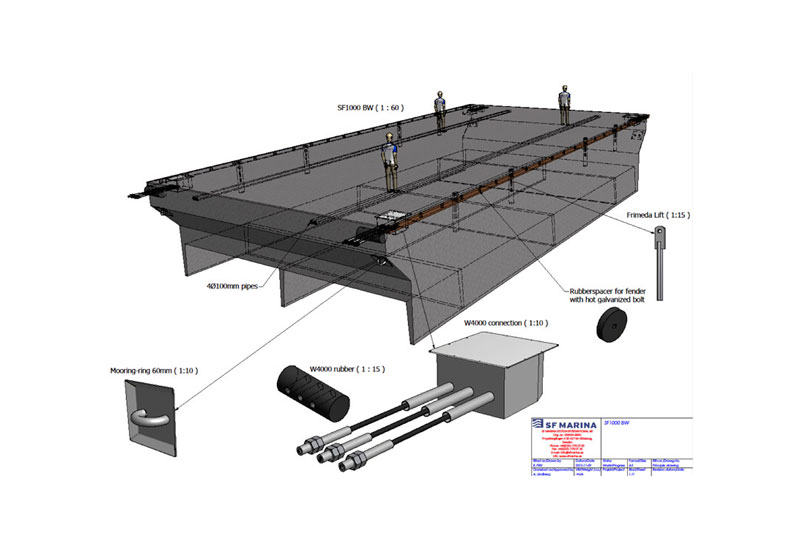

SFBW 1000 Project

SF BW1000 Floating Breakwater

- 32' wide, 12' tall, 66' long standard size

The SFBW1000 is SF Marina System's largest production floating breakwater. The massive 32' x 66' unit weights 150 metric tons (330,000 lbs) and is available for delivery via ship worldwide.